In this article, I analyse the reasons for the decline of the Longwy Enamel Manufactory and propose a three-step marketing plan to revive the bicentennial Lorraine brand.

The Longwy Enamels are my entire childhood. I come from Lorraine and when I was a child, every Lorraine household had some. I saw them at my grandmothers’, my father sold them in his shop. So it is with a pang in my heart that I look today at the situation of the Longwy Enamel Manufactory. This Lorraine institution perpetuates a century-old know-how, it is listed as intangible cultural heritage, and yet it finds itself once again on the brink of financial collapse. But how did this historic manufacture, which survived two world wars and multiple restructurings, end up here? And above all, what solutions can be imagined to make Longwy enamels attractive again? I have looked into the subject, and as you will see in this dossier, I come with concrete proposals. I hope you will like them. Feel free to leave your comments under this article.

Contact IntoTheMinds for your marketing studies

Key takeaways

- The manufacture is facing a major financial crisis that has led its director to launch a crowdfunding campaign

- 7000 shares are also offered to the public to save the company

- This situation reveals deep structural problems in the French decorative arts industry

- The company’s complicated situation stems partly from its positioning and partly from its sector, the decorative arts, which is no longer in vogue

- To ensure the long-term survival of the Manufacture, it is essential to change its positioning and associate it with the world of luxury

- To trigger impulse purchases, the pricing positioning must also be reviewed and operational solutions found to offer cheaper objects

A crisis that did not come out of nowhere

To understand the current situation of Longwy enamels, we must first grasp the complexity of this unique manufacture. Since 1798, this family then industrial company has developed a unique enamelled ceramic technique. The cloisonné on faience process, invented in 1870 by Amédée de Carenza, remains an almost unique know-how in the world.

But precisely, this technical excellence paradoxically constitutes one of the company’s weaknesses. Each piece requires up to 100 hours of artisanal work, 7 different crafts and 4 successive firings. In a world dominated by production speed and cost reduction, this artisanal approach becomes a colossal economic challenge. Production costs can only be offset by a very premium positioning, which is precisely the Achilles’ heel of Longwy Enamels. The products have always been considered decorative objects rather than luxury objects. We will come back to this.

Added to this is the human resources challenge. The manufacture currently employs about thirty specialized craftsmen, some of whom master techniques passed down from generation to generation. Training a new enameller takes several years, making the company particularly vulnerable to departures and market fluctuations.

Finally, I cannot help but draw a parallel with Borsalino. I devoted an article to this legendary brand when its bankruptcy was announced in 2018. I pointed out that even such flagships of heritage, centuries-old, can die because of inappropriate positioning.

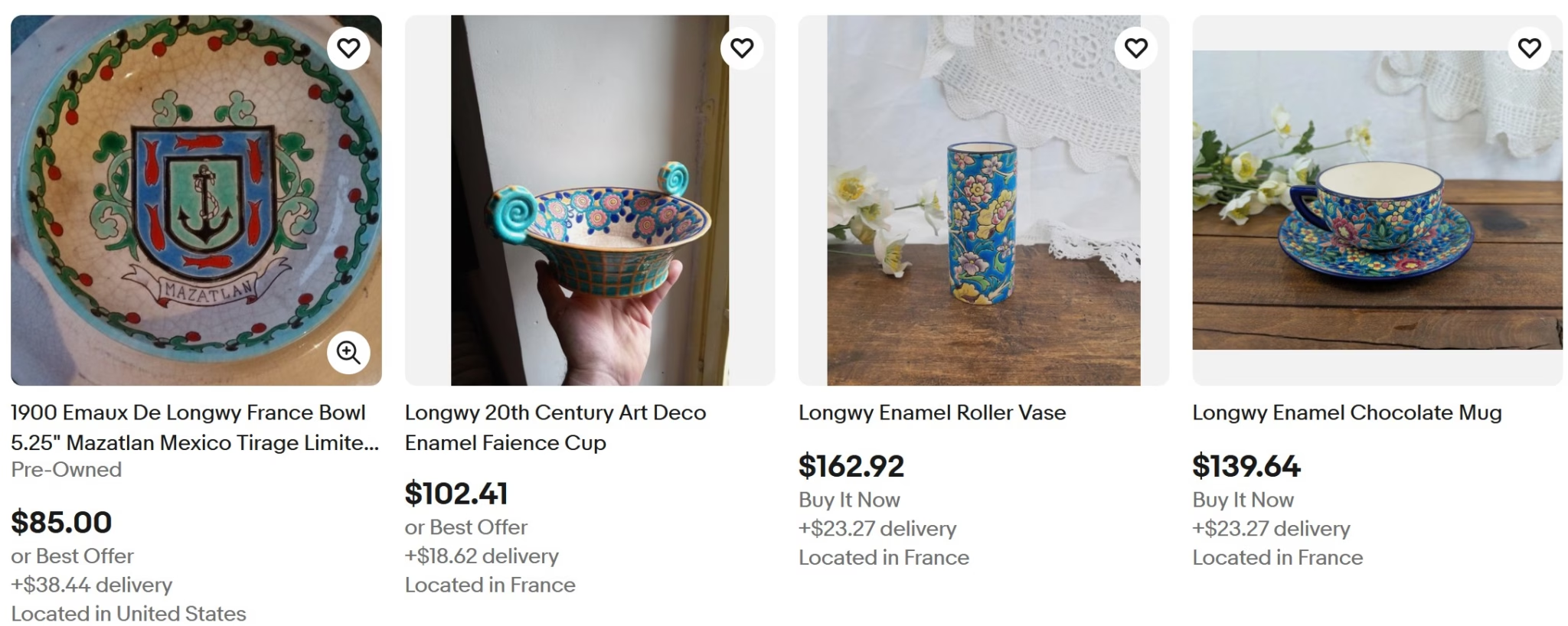

Longwy enamels are very numerous on classified ads and second-hand sites. Abundant production has made these objects very common and has driven prices down. They are therefore not perceived as very desirable objects and only interest a handful of specialists.

At the roots of chronic fragility

This new crisis is unfortunately not the first. The Longwy manufacture has already experienced several difficult episodes, notably in the 1980s and 2000s. Each time, short-term solutions were found, but the structural problems were never truly resolved.

The French decorative arts market suffers from fierce international competition. Asian productions, even if they do not reach the quality of Lorraine enamels, offer prices that defy all competition. At the same time, consumer tastes are evolving towards more functional and less ornate objects. And then, it must also be emphasized, the Decorative Arts are no longer at the center of consumers’ interests, particularly those of the younger generation. You need some culture to appreciate these objects, and at the risk of sounding like a boomer, the culture of traditional know-how tends to be lost.

The traditional clientele of Longwy enamels is therefore aging, and the company struggles to attract new generations. Despite collaborations with contemporary designers such as India Mahdavi or Vincent Darré, the brand remains perceived as disconnected from current trends. This is a shame because it enjoys enormous brand awareness and the base is therefore there to make it a different brand.

From a financial point of view, the cost structure of the manufacture poses a problem. Fixed costs are significant (2000 m² premises, specialized equipment, qualified payroll), while revenues remain irregular and dependent on one-off orders.

The call for help: 7000 shares to survive

Faced with this critical situation, the management made a courageous decision: to open the capital to the public. This crowdfunding operation offers 7000 shares to individuals and companies wishing to support the manufacture. It is reminiscent of what happened with Duralex, with the difference that Duralex does not really have unique know-how and sells a product with little differentiation compared to Chinese products. A glass remains a glass, regardless of where it is made. A Longwy enamel object, on the other hand, cannot come from China. This object is simply attached to the history of Lorraine and the History of France. From a marketing point of view, this is a unique advantage that must be exploited.

Martin Pietri, director of the company, does not hide the gravity of the situation. Without this capital injection, the manufacture risks closing its doors permanently, taking with it an irreplaceable industrial and cultural heritage.

This approach fits into a broader trend of democratizing the financing of heritage companies. Other French manufactures have already experimented with this type of approach with varying success. The advantage lies in creating a community of shareholder-ambassadors, potentially more committed than a traditional investor.

However, this solution can only be a first step. The money collected must be used to finance a real transformation of the company, not just to plug a temporary financial hole.

How to get Longwy enamels out of the crisis?

Moving upmarket

To durably emerge from this existential crisis, the Longwy Enamel Manufactory must fundamentally rethink its approach. From a strategic and marketing point of view, I believe there is only one solution for the products: moving upmarket. Let’s say it straight away, I do not believe in a takeover of the Manufacture by a luxury group. The know-how is certainly unique, but the Decorative Arts are no longer in vogue. A luxury group could therefore not make the investment profitable. No. The change must come from within.

The Manufacture has already ventured into the luxury field. But as it does not really have the legitimacy to do it alone, it has partnered. I am thinking in particular of the partnership with Patek Philippe for the manufacture of clockettes. I leave you to admire the fabulous example that I photographed in 2022 and which testifies to the know-how of the Lorraine craftsmen. It is truly beautiful. The problem is that these clockettes are unique pieces, and they only sell a few copies per year which is not enough to make it a sustainable source of income. But the idea would be to multiply opportunities of this type.

Luxury brands rely on creating an imaginary world, nostalgia, and all ancestral know-how can perfectly fit into this strategy. This is the vein that LVMH exploits with Vuitton and Moynat for example.

Customer experience at the Manufacture

Customer experience represents another major lever. I believe that the manufacture could develop its activity of visits and participatory workshops. Industrial tourism is experiencing remarkable growth, and visitors are often willing to pay to discover authentic know-how (see video below). Initiation courses or personalized creation formulas could generate significant additional revenue. Moreover, the purchase rate after a visit exceeds 50%, which can only be positive for the factory shop. This seems to me all the more important as the number of points of sale has melted like snow in the sun (there are only 22 left in France).

Digitalization, long neglected, becomes essential. A high-performance online shop, strengthened presence on social networks, collaborations with influencers specialized in the art of living… So many tools to reach new audiences and rejuvenate the brand image.

Innovation serving tradition

Another line of thought is to look towards innovation. I believe that innovation and tradition are not necessarily opposed. The manufacture could explore new production techniques that preserve quality while optimizing costs. If the current positioning is maintained, this seems to me an essential step. We must simplify and automate the steps where the human hand is not essential, and keep human intervention only for the value-added steps that are the signature of the Manufacture.

It must be possible to offer cheaper objects that can trigger impulse purchases. The Meisenthal glassworks understood this. They worked on their marketing to promote their glass Christmas baubles at €28 and release a different bauble every year. The success was there (45,000 baubles sold) because it is an accessible object whose pricing was well studied. Conversely, Christmas baubles in Longwy enamels cost between €55 and €280. That is far too expensive. We must find a way to simplify the process (and make it lighter because each bauble weighed nearly 1/4 kg, making them unusable).

Artistic collaborations must also be intensified. Each partnership with a recognized creator generates media visibility and attracts new collectors. Contemporary art and Longwy enamels can create synergies provided the artists are in the spirit of the times. But it is imperative to seek out artists who are known to younger generations. Current collaborations are too confidential.

International markets represent an underexploited potential. Lorraine enamels could particularly appeal to Asian and American markets, fond of authentic French craftsmanship.

We must diversify production towards more ostentatious objects that say something about the person who owns them. We must sell positioning goods.

What solutions to save Longwy enamels?

The Longwy enamels crisis perfectly illustrates the challenges facing French heritage companies. Between preserving authenticity and the need for economic adaptation, the balance remains precarious. The foundations of this company are solid and nothing is lost. It is first and foremost a marketing job that must be done. Proof of this is the success of the Meisenthal Manufacture, also in Lorraine. Its products are highly sought after and tradition can therefore be perpetuated.

To save the Longwy Enamel Manufactory I have imagined several solutions that I present to you below.

1. Reawaken the desire for Longwy enamels

As a first step in the renewal of Longwy enamels, I believe we must go through collaborations with artists and personalities who speak to younger generations, and encourage them to create objects that can be worn by younger generations. The problem with Longwy enamels is that they are objects that remain inside the home. To popularize them, they must be taken out of the home, made less confidential, more visible.

In short, we must restore brand awareness among younger generations and disseminate the know-how through objects that are seen.

2. Associate Longwy enamels with the world of luxury

The second step consists in changing the positioning of Longwy enamels and associating them with legitimate brands in the luxury universe. As I explained, the cost structure imposed by the implementation of this know-how is only viable with a premium/luxury positioning. The problem is that Longwy enamels are not associated with this segment. To change this, I suggest capitalizing on the partnership with Patek Philippe and seeking others, less confidential, in other categories: leather goods, clothing, accessories, …

I have imagined initial collaborations with Hermès and Louis Vuitton. First around the Louis Vuitton universe with objects belonging to the current universe of Longwy enamels but declined to bear the Louis Vuitton monogram. It is therefore a co-branding that would allow current Louis Vuitton customers to discover Lorraine know-how.

I then thought about accessories that could accompany luxury leather goods. Longwy enamels could appear as jewellery for luxury bags. This would have the immense advantage, if these bag jewellery were sold in the boutiques of the brands in question, of immediately legitimizing the Lorraine brand and making them desirable.

Hermès could also imagine a limited edition of the padlock for its Birkin bag. It is the most coveted bag on the planet. Longwy enamels would immediately acquire icon status in luxury.

And of course, we cannot talk about luxury without talking about watchmaking. The collaboration with Patek Philippe is limited to clockettes, very confidential. We must absolutely seek to break through with a limited edition wristwatch. And in a second step, I suggest initiating other collaborations with the rare watchmaking manufactures that still have a department dedicated to special techniques (enamelling, micro-marquetry): Vacheron Constantin and Jaeger-LeCoultre.

Patek Philippe watch with dial made in Longwy enamels (inspired by a real clockette presented during the 2022 ‘The Art of Patek Philippe’ exhibition).

3. Get out of the moribund sector of Decorative Arts

To save Longwy enamels, we will have to hurt ourselves and abandon the Decorative Arts niche. It is no longer carrying. It does not transmit social positioning like luxury brand accessories do. We must therefore diversify production towards more ostentatious objects that say something about the person who owns them. It is vanity, certainly, but today that is what works. I leave you to look at the growth of the luxury sector in recent years to convince yourself.

Frequently asked questions about the Longwy enamels crisis

Why is the manufacture going through yet another crisis?

The current crisis results from several factors: high production costs linked to the artisanal process, increased international competition, products unsuited to demand and difficulties in renewing the clientele. Despite its technical excellence, the company struggles to balance its accounts in a changing market. There is also a question of price. The objects are too expensive for them to become impulse purchases. Proof is the success of Meisenthal Christmas baubles. The Meisenthal glass centre sold 45,000 because the price was attractive (from €28). Longwy enamel Christmas baubles cost between €55 and over €200.

What do the 7000 shares offered to the public represent?

This crowdfunding operation aims to raise funds to ensure the immediate survival of the manufacture. It also makes it possible to create a community of shareholder-ambassadors potentially more committed to the development of the company.

Do Longwy enamels still have a future?

Yes, but this requires a profound transformation of the economic model. Above all, the brand must be given legitimacy in the luxury universe and made known to a wider public. Product diversification, development of industrial tourism, digitalization and technical innovation can give new life to this historic manufacture.

How can an individual support the manufacture?

Several possibilities are available to individuals: participate in the capital increase, buy products from the manufacture, visit the workshops, or simply make this exceptional company known around you. Every gesture counts to preserve this unique heritage.

Does this crisis affect other similar companies?

Unfortunately yes. Many French heritage companies face the same challenges: high production costs, international competition, difficulties in transmitting know-how. The situation of Longwy illustrates a broader problem of French craft industry.