For this 2.5-hour visit, Mousse Jacquier, Blancpain’s PR assistant, welcomed us. Although I feared that we’d have to stay behind windows to observe the watchmakers, I was positively surprised to be able to get into the most prestigious departments (Tourbillon, Minute Repeater, Finishing, Engraving) and to interact with the watchmakers freely.

Tourbillon Atelier

Two watchmakers were at work when we went in. After we got introduced, the principle of the Tourbillon was quickly explained. One of the watchmakers then presented his work: the parts necessary for the assembly of the Tourbillon are delivered in batches of 5. Up to two weeks are necessary to assemble 5 sets. A demo movement was put under the binocular microscope to reveal the Tourbillon’s magic.

The possibility remains, however, to adjust the watch to the very way of life of the owner.

The adjustment is made possible by little screws placed on the cage of the Tourbillon. Screwing more or less modifies the balance. When asked, “How do you know which screws to adjust ?” the watchmaker answers with humility, “experience.”

Minute Repeater Atelier

After the Tourbillon Atelier we were about to see the Holy Grail, the Minute Repeater atelier. On the day of our visit only one (out of 3) watchmaker was at work. He was in charge not only of Minute Repeater but also of the Equation Marchante and even took over the assembly of a 1735, the most complicated watch ever manufactured by Blancpain when a colleague of him left.

Once again, the principle of the minute repeater was explained before a movement was put under the microscope (linked via a camera to an LCD monitor). The movement could then be observed at leisure, especially the upper side, which is usually hidden under the dial and as fascinating as the backside. The watchmaker then activated the mechanism. We saw the hammers hitting the gongs … a very magical moment. But it all went too fast! I couldn’t take my eyes off the screen. This was all so eye-catching but remained mysterious. The watchmaker manually activated the repeater and slowly went through every part to show us how each part triggered the next one. It’s just amazing to see how each part is designed to accomplish a given function and how that function shapes the part.

We learned that the “gong” is made of a special alloy, a stock purchased by Blancpain 50 years ago. The same stock is still used to produce about 20 repeaters yearly. With 10 cm in each repeater, you can do the maths by yourself and find out how many meters were used in the last 25 years; very little actually for a quarter of a century. Each movement requires about 1 month of work to be assembled … compare this to the time needed for a Tourbillon, and you quickly understand the price differences.

There’s also a big safe out there, and look at what is in it: the very last 1735 sold (the 30th). There’s no need to comment on who likes fine horology. The dream has (or more precisely “had”; it’s sold out) a price: 1,200,000 CHF (about 800,000€). The movement is first assembled, tested, then disassembled, and re-assembled again in the case before the whole watch is tested again. It all takes about 1 year to “produce” (I hate this “word”; in Blancpain’s context, only “manufacture” seems to fit) the watch.

A little story to finish on the 1735: sometimes, the 1735 was delivered to the lucky owner by the watchmaker who assembled it. Mousse Jacquier told us that the watchmakers sometimes made photo albums to accompany the birth of 1735 along the seasons. When you live on the other side of the earth, getting news of your baby and seeing its evolving environment must be a very particular feeling.

Last but not least, Blancpain also specialized in libertine minute repeaters (with automatons depicting an erotic scene). The production of repeaters is already very limited; that of libertine repeaters is even more confidential, and for the first time, I’ve seen one exemplar in person. The automatons are realized in gold by an external craftsman. All watches produced with automatons are unique exemplars as no two very same scenes are produced. The craftsman went very far in the details; look at the book, which is engraved with an erotic scene.

On our way from the Minute repeater atelier to the Finition atelier, we stopped at a showcase prepared for one of the Basel fairs where all components of the 1735 were on display. No wonder that it takes so long to assemble them.

Finishing Atelier

In the finishing Atelier, all hidden parts of the watch are decorated: Côtes de Genève and other decorations are realized by a team of 6 people. This is, however, reserved for the most prestigious movements: 1735, minute repeaters, and some (not all) of the tourbillons. For the less prestigious movements, finishing is realized by pre-programmed machines.

For a minute repeater, the different steps of the finishing process are realized, starting from rough parts received from Frederic Piguet SA. It takes 1 month to prepare a set of parts before being handed over to the Minute Repeater Atelier to assemble. Finishing is realized using, in many cases, custom-made tools (see also the article by Jeff Kingston in the Lettres du Brassus).

To sum up, the Finishing Atelier adds value to the watch. However, it’s a hidden value that only the owner can appreciate through the display on the back.

Engravings Atelier

This Atelier was already dealt with in a thorough article by Didier Schmutz in the Lettres du Brassus. I won’t describe better how this Atelier works; I suggest that the reader follow the hyperlink and read the original article.

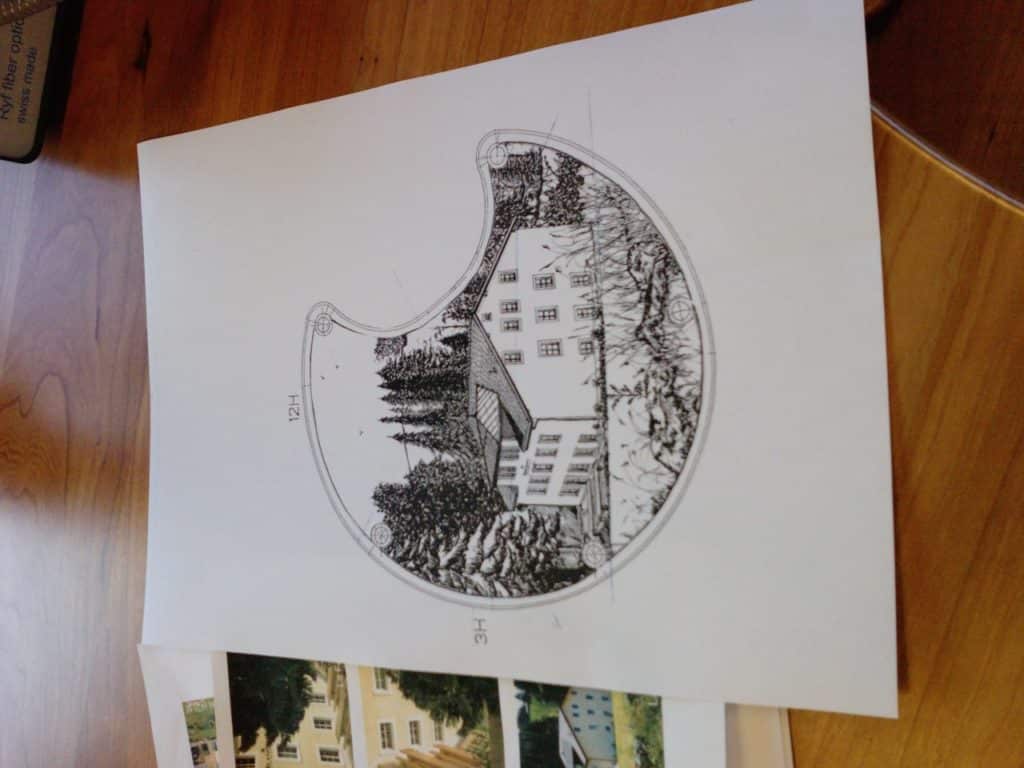

I was fortunate enough to see the realizations of the engravers who all graduated from the Ecole Boule in France. In particular, I saw a series of 50 rotors in gold for a limited edition dedicated to the Chinese market. In this Atelier, we were leaving the world of craftsmanship to enter that of Art.

The visit ended in the meeting room, where we were given merchandising articles, which perfectly show Blancpain’s attention to detail and quality.

It doesn’t matter whether you’re a customer or not: a visit from the manufacturer in Le Brassus is always possible (after an appointment, of course). The visit is an extraordinary moment for an amateur or a passionate collector. Blancpain shares with you the secrets of the manufacturing process of a high-end time-keeping object. After such a visit, you will never dare to ask why such watches are priced so high.

To come back to a more marketing-oriented analysis, welcoming amateurs, potential clients, and clients the way Blancpain does is just a great communication and loyalty tool (believe me, the professionalism of Blancpain employees counts for a large part, especially as far as Mousse Jacquier is concerned): putting a face, a name, on such a delicate and qualitative object is a rare experience in an industrialized world where banalisation has become the rule. Blancpain sets up a new standard in how a company can communicate with prospects and clients. The initiatives of the watchmakers (delivering the watch in person for the 1735, taking pictures of the watch’s birth along the seasons, sharing their passion with the visitors, etc.) are also crucial as they tend to create a personal relationship with the owner and the visitors. Emotional aspects are especially important here (remember that lifetime loyalty is created through an emotional bond with a brand, which Blancpain very well manages).

For those of you who are contemplating the purchase of a watch and who think of the choice of their watch as more an intellectual process than an impulsion, I think Blancpain has developed for you a remarkable solution that is backed by their magazine « Lettres du Brassus.» I’m convinced that very few brands can propose such proximity with the very people at work; the added value in terms of branding is enormous and deserves to be communicated in the not-so-little world of watch enthusiasts.

Once again, my deepest acknowledgments to the Blancpain team and, in particular, to Mousse Jacquier for enabling this visit.

Posted in Marketing.